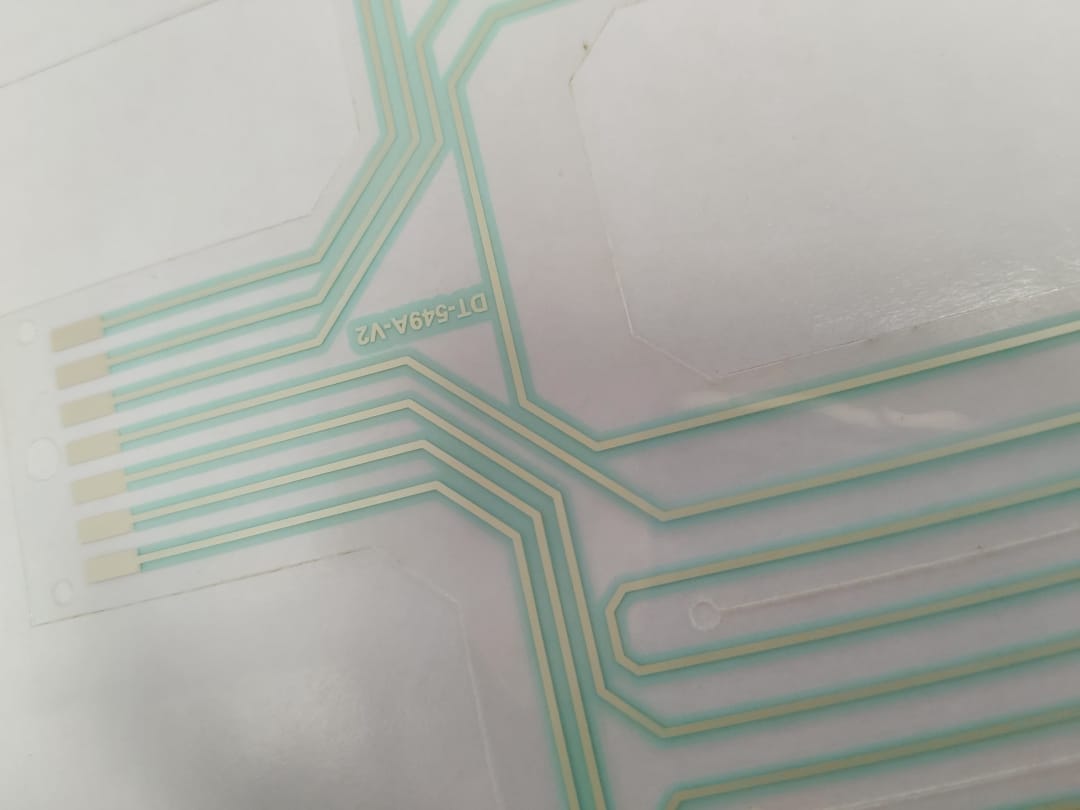

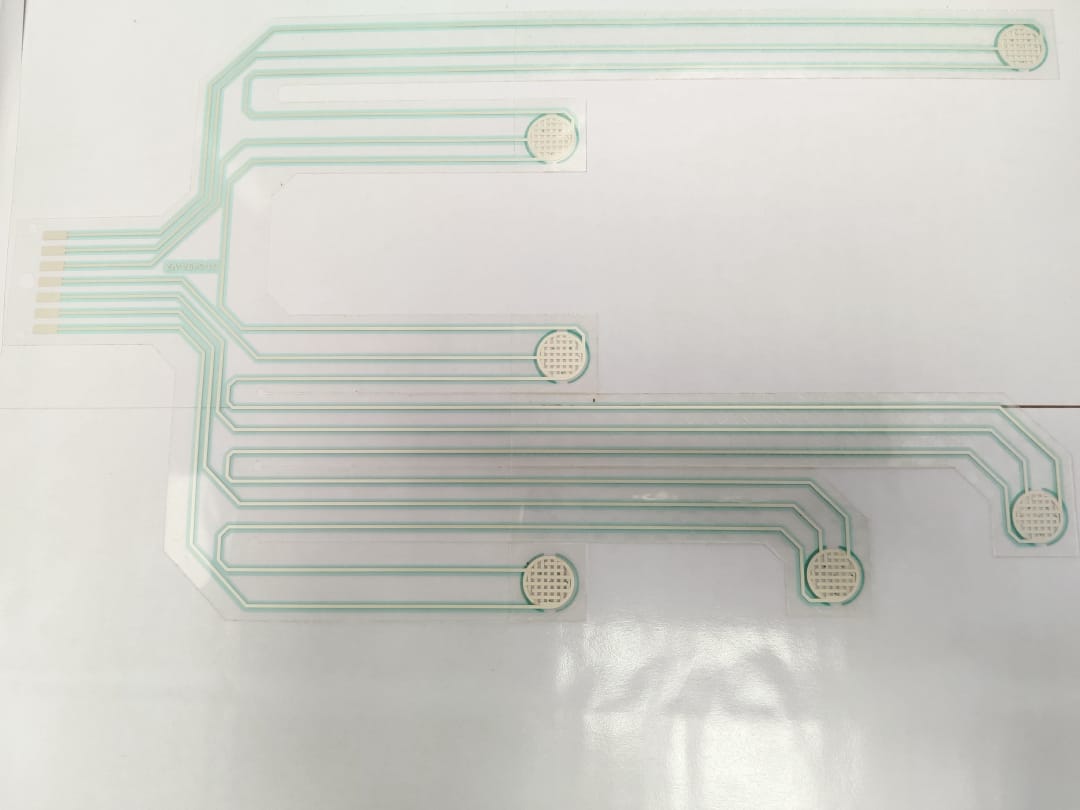

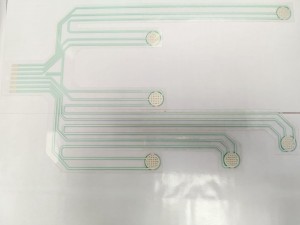

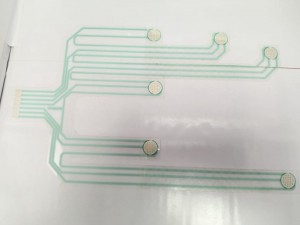

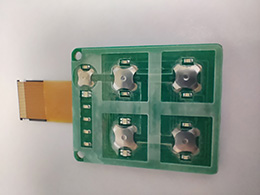

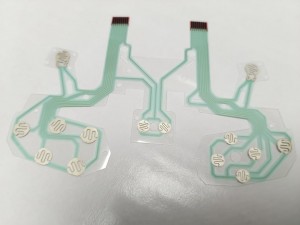

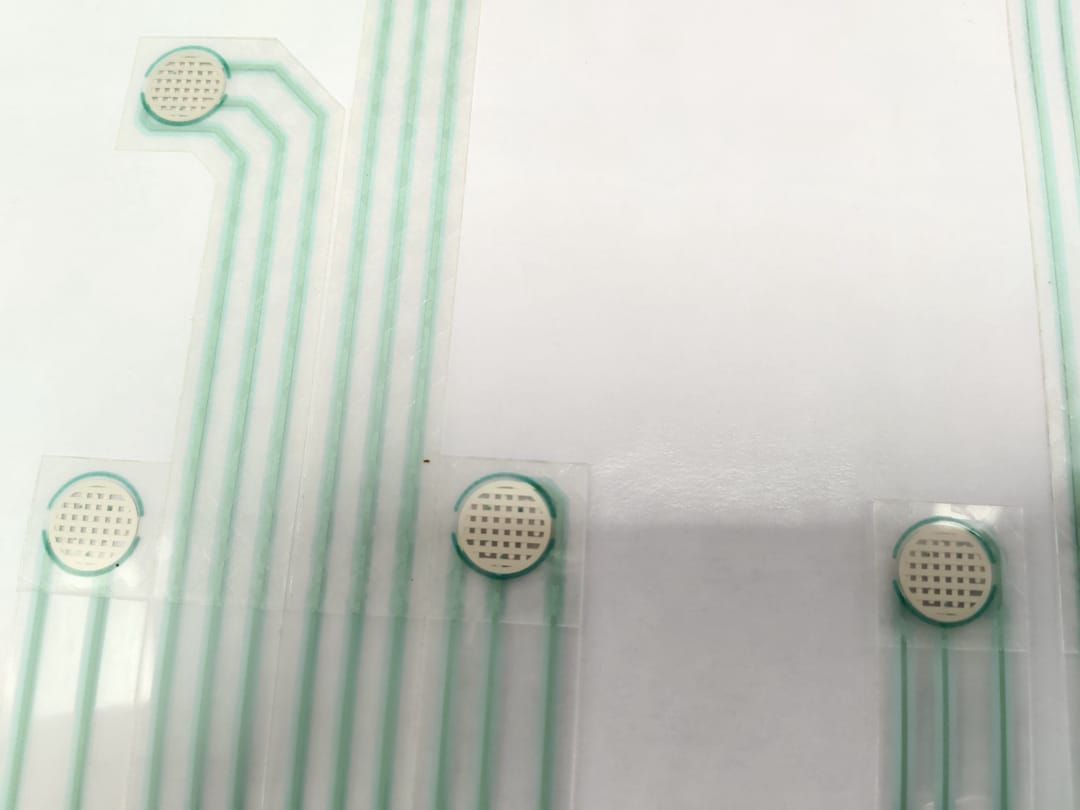

Silver chloride printing membrane circuit

Application

The circuit is printed onto the membrane using a specialized printer that uses conductive inks containing particles of silver chloride. The ink is deposited onto the membrane in the desired pattern using a computer-controlled printing head. Once the circuit is printed, it is typically encapsulated in a protective coating to prevent degradation and corrosion of the silver chloride. Silver chloride printing membrane circuits have several advantages over traditional circuits, including their flexibility, low cost, and ability to operate in the presence of fluids. They are often used in medical and environmental monitoring applications, as well as in wearable technology and smart textiles.

The silver chloride printing circuits are the perfect choice for high-quality electronic applications. these circuits are printed on a transparent polyester substrate, making them highly durable and insoluble in water. The circuits are designed to be flexible and provide excellent electrical performance, making them ideal for a wide range of projects. The silver chloride material is also resistant to corrosion, making it a reliable choice for long-term use. With these circuits, you can be sure of reliable performance and superior quality.