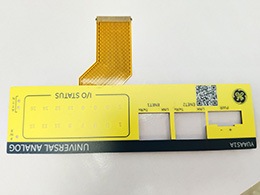

FPC circuit design membrane switch

Application

The membrane switch build with a membrane overlay, adhesive layer, and circuit layer, making it ultra-thin and easy to design. It is designed to last for a long time and withstand the wear and tear of everyday use. It is also designed to be resistant to dust, dirt, and other environmental factors, making it a great choice for a variety of applications. The membrane switch also offers a range of options. The user can customize the look and feel of the switch, making it easy to use and aesthetically pleasing. It can be customized to fit any application, from simple to complex.

The membrane switch can choose to use the FPC or choose the PET silver paste as the bottom circuit, the below is the main differences between FPC (flexible printed circuit board) circuits and silver paste PET circuits :

1. Different materials: FPC circuits usually use polyimide film as the substrate, while PET silver paste circuits use polyester film as the substrate.

2. Different production processes: FPC circuits are usually made by cutting, stamping, electroplating or copper plating processes of flexible substrates. PET silver paste circuits are made by printing process using the conductivity of silver paste and the flexibility of polyester film.

3. Different flexibility: FPC circuits are relatively thin and the material is flexible, which can be used for curved and irregular electronic products. PET silver paste circuits are relatively hard and must be laid in a flat way.

4. Different application scope: FPC circuits are suitable for design complex membrane switches which need many electric components design and low loop resistance. While PET silver paste circuits are usually used for the standard membrane switch which don't have many circuits routings.

In conclusion, although FPC circuits and PET silver paste circuits have similar functions, they have different manufacturing processes, material characteristics, and cost, and need to select the appropriate products according to specific needs.