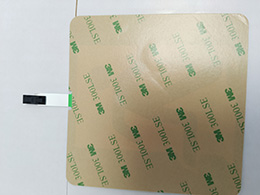

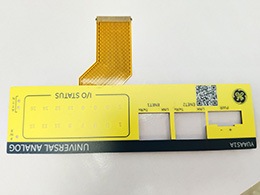

Double layer membrane switch

The double side overlay membrane switch also have the membrane circuit on it, the such membrane switch is a versatile control switch that can be used in a variety of applications. It has a flexible circuit design and electric function, making it ideal for controlling a range of devices. The switch is designed and custom to meet the needs of the user, and the process is easy to follow.

The membrane switch is made from a thin, flexible material that can bend and flex to fit the user’s needs. It is designed to be durable and long lasting, making it a reliable choice for any application. The switch is also designed to be easy to operate, with simple push buttons and a smooth action. The membrane switch can be used to control a variety of devices, from simple on/off switches to more complex systems. It is also highly customisable, allowing the user to design the switch to fit their specific needs. The switch is also designed to be easy to install, with minimal wiring and setup required. The membrane switch is also designed to be cost-effective, as it can be used in multiple applications. It is also designed to be energy efficient, using minimal electricity to power the switch. This makes it a great choice for anyone looking to save money on their energy bills. Overall, the membrane switch is a great choice for anyone looking for a versatile, cost-effective, and energy-efficient control switch. It is designed to be flexible, easy to install, and highly customisable, making it a great choice for any application. With its flexible circuit design and electric function, the membrane switch is sure to provide reliable performance for years to come.

For a reliable, cost-effective, and customizable special switch, choose the Double Layer Membrane Switch.

ll-round 360 production line cutting group stop workflow, enabling automatic tube feeding, automatic feed, automatic cutting, automatic transmission operation.

2.Using KASRY Nesting programming system as a major programming tool, the software programming platform AUTOCAD basic, simple, graphical and intuitive, feature-rich, it can greatly improve operational efficiency.

Application

1.all-round 360 production line cutting group stop workflow, enabling automatic tube feeding, automatic feed, automatic cutting, automatic transmission operation.

2.Using KASRY Nesting programming system as a major programming tool, the software programming platform AUTOCAD basic, simple, graphical and intuitive, feature-rich, it can greatly improve operational efficiency.

3.High-end three-dimensional flexible robotic cutting applications, to achieve bevel cutting function, the pipe and the torch using the servo positioning function .

Can cut carbon steel, stainless steel, copper, aluminum and other pipes and profiles, such as: the tube, pipe, oval pipe, rectangular pipe, H-beam, I-beam, angle, channel, etc. The device is widely used in various kind of pipes profile processing field, shipbuilding industry, network structure, steel, marine engineering, oil pipelines and other industries.